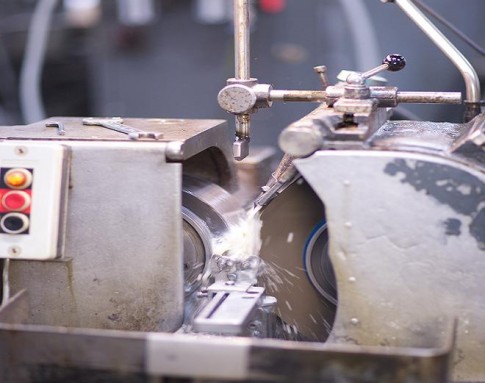

We also offer subcontracting services for chopping materials with this machine.

Materials: steel, cast iron, stainless steel, aluminium, copper, brass, plastic.

Maximum diameter of the material: D 250 mm.

Minimum diameter of the material: D 6 mm.

One of our own production articles is aluminium profile doors. We manufacture the doors from custom made aluminium profiles based on the customer’s dimensions and the tone variation and glass details offered by us.

In case of interest please send us an inquiry, so that we could describe the offered solutions more thoroughly.

One of our own production articles is aluminium profile doors. We manufacture the doors from custom made aluminium profiles based on the customer’s dimensions and the tone variation and glass details offered by us. In case of interest please send us an inquiry, so that we could describe the offered solutions more thoroughly.

Our company is established in 2007 and we are engaged in manufacturing elevator components and other details.

We care about:

QUALITY

Quality is assured by competent employees, carefully selected suppliers and raw material, high-tech equipment and functional process management together with constant improvement of the production process.

SECURITY OF SUPPLY

Security of supply is one of the major factor for our customers and thus we carefully select our cooperation partners (i.e., the suppliers) and assure continuous control of production processes and inform our customers immediately even about the smallest delays.

PRODUCT DEVELOPMENT

We regularly visit trade fairs in order to get acquainted with the new processing technologies and development trends and attempt to implement the most up-to-date production solutions in our company. In cooperation with our customers, we complement the functionality of our products and develop new solutions in order to satisfy the needs of the market.

CUSTOMER SATISFACTION

We measure customer satisfaction, in the framework of which we expect proposals from the customers on how to improve our services and products.

CONTINUOUS DEVELOPMENT

We have set our aims and measure the accomplishment of those aims and continuously attempt to improve our management system.

HME quality policy is approved by our CEO René Reimer on 22.05.2013.

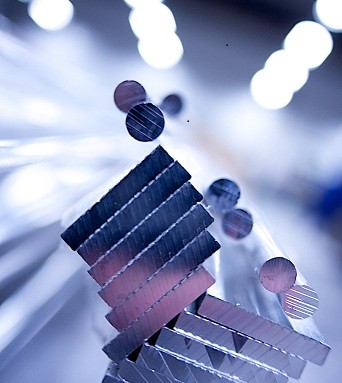

HME was established in 2007 with an aim to offer high quality complex services in the field of mechanics: from the customer’s idea to our realisation. In the first year of activity, we launched manufacturing in a 940 m2 site and started to manufacture different stainless steel pump details. Additionally, we started preparing the transition of the production of different elevator details from Sweden to Estonia. This process was completed in 2008. In 2009 the company complemented its existing machine park and started active work for finding new customers. In 2010 we obtained a new CNC lathe and also moved to a new production site at Paneeli 2B, Tallinn, with the total area of 2,200 m2. In 2011 we completed our next investment plan and obtained new equipment in order to substantially increase our production capacity and execute orders more effectively. From there on, our machine park consists already of 12 machine tools and different manual equipment.

We service customers in Estonia, Finland, Sweden and Germany.

Our main aims in 2012–2013 were to install the obtained equipment, improving manufacturing activities and introducing a quality management system. As of 2013, our management system is certified according to ISO 9001:2008 standard, verified by Bureau Veritas.

The aim of HME is to continuously assure high quality and security of supply for our current and future customers. We can achieve our aims in cooperation with our wonderful customers and through constant development of HME.

10.2011

As of now, HME offers subcontracting possibility for round grinding of metal details. You can use different grinding equipment from inner grinding to centreless grinding machines. The volume of a batch is up to 20,000 a month. We are always ready to answer your questions about our grinding capacity.

We are always ready to answer your questions about our grinding capacity.

08.2010

We have moved to a new location with the address Paneeli 2B, Tallinn. The new and contemporary premises are more suitable for metal processing and assure a better production environment for our team. The new building, professional team and comprehensive technological possibilities allow versatile approach to the realisation of your ideas. Our total metal processing surface now totals to 2,100 m2. We welcome our current and new customers to get acquainted with our building and metal processing possibilities — from an idea to a complex assembly.